The background:-

The EGR system is designed to allow a certain amount of exhaust gas back into the engine cylinders via the inlet manifold. This is to reduce NOx emissions from the engine by replacing some of the oxygen in the pre-combustion mixture in a diesel engine.

An unfortunate side effect of this is to produce heavy carbon gunk build-up in both the EGR valve and the inlet manifold. Further, it is said that the mechanical part of the valve, directly in the line of intake air-flow, reduces the performance of the car as well as exacerbating the carbon contamination by providing a further surface for the crud to build up, thereby reducing, in a sort of vicious circle, the cross section of the air inlet tract at that point. The EGR is connected directly to the inlet manifold.

Some time ago, a bypass was designed whereby the EGR was replaced with a straight through tube and the exhaust gas pipe was blanked off. This certainly reduces the amount of contamination and is said to increase performance. Whether it does improve things is beyond the scope of this post though

The problem:-

There are two types of exhaust gas pipe (see attached diagram), with flanges at either end on the short pipe and at one end on the long pipe and these are separate items, secured to the pipe by either brazing, welding or some other process, to produce a gas tight pipe. The problem is that these flanges are separating from the pipe allowing some escape of exhaust gas.

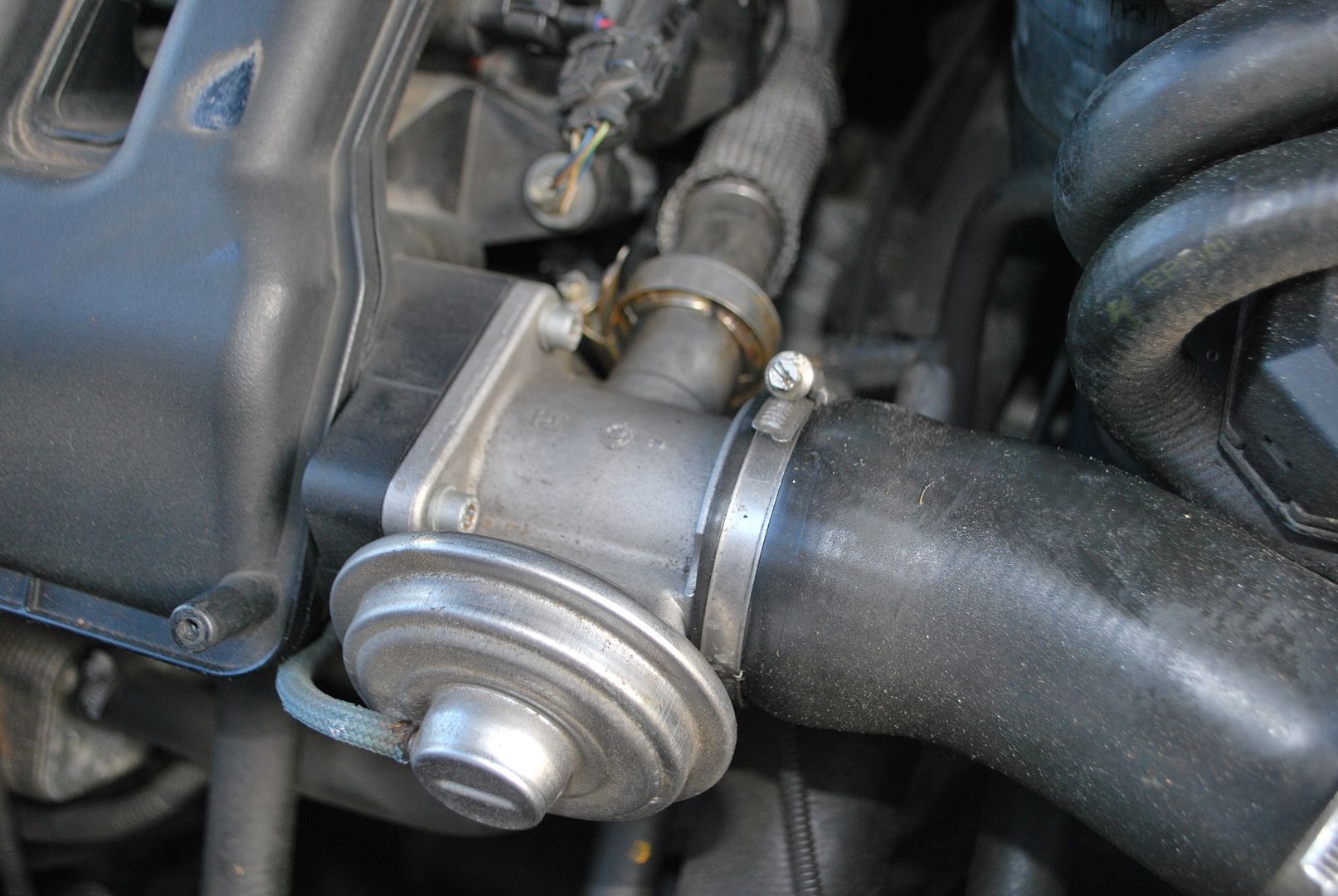

The photograph illustrates the short pipe with flanges at both ends. The diagram illustrates the shape and location of both pipes, numbered 3 and 13 in the diagram.

If you have an EGR bypass on your car, it might be worth removing the engine cover and examining the pipe, whether it be the long or short pipe. However, the flange(s), even if broken away from the pipe appear to be secure owing to the tension between the pipe and the EGR bypass blanking stub so it might be as well to unbolt the EGR bypass from the inlet manifold to release the tension on the exhaust pipe and thereby positively to identify whether there is a problem or not.

On my car, there appears to be no indication of the problem in terms of engine performance or any other obvious symptoms so I would think that physical inspection would be the only way to be sure. Having said that, of course, exhaust gas escaping from the exhaust manifold can't be good, can it?

A probable, though not proven, reason is that the exhaust gas, with nowhere to go upon reaching the blanking stub, pressurizes the pipe beyond design limitations, causing failure of the flange joints.

Possible solutions

One solution to this is to replace the pipe or get the flange(s) re-attached but apparently the same thing will happen again. Lyndon came up with a permanent solution however, and it is the solution I am having done on my car.

Following installation of the EGR bypass, the exhaust gas pipe is redundant, so it can be removed completely from the EGR bypass to the exhaust manifold, and the port in the manifold can be welded over.

Lyndon tells me that although the pipe flange joints on his car failed on several occasions, he has never had a problem since the pipe was completely removed.

The time taken for the inspection, including removal and replacement of the engine cover and the EGR bypass, was less than 30 minutes, even for a mechanical numptie like me so in my view, a worthwhile investment in time and effort

A Caveat

I haven't heard of this fault occurring on cars which have a functioning EGR valve but, who knows? As I said before, there were no obvious symptoms. In fact, my car is in normal daily use at the moment until I get her into the garage next week for the welding to be done.

You do not have the required permissions to view the files attached to this post.

works for me

works for me