raistlin wrote:Received wisdom has it that one should never allow the fuel level to go below 1/4 of a tank in order to maintain the life of the fuel pumps, owing to the "saddle" shape of the tank.

The fuel level has no effect on the service life of the pumps. The quarter tank mantra is a practical consequence, a work around for a failed ITP. The ITP is centrifugal and in twin pump systems tends to wear out the commutator. It's due apparently, to the brushes being too hard. When this happens, the ITP stops running. This is where the quarter tank level becomes important. The UBP is a positive displacement type and is actually able to draw fuel from the tank unassisted by the ITP. It's working overtime in doing so, but some manage it for thousands of miles. However, the fuel comes via the now stationary ITP. There's a pressure activated priming valve in the ITP which remains open when the pump's not running. The UBP will pull air into the line via this valve unless the valve is submerged. It needs - you guessed it - around a quarter tank level to do that. The overtime often causes premature failure of the UBP.

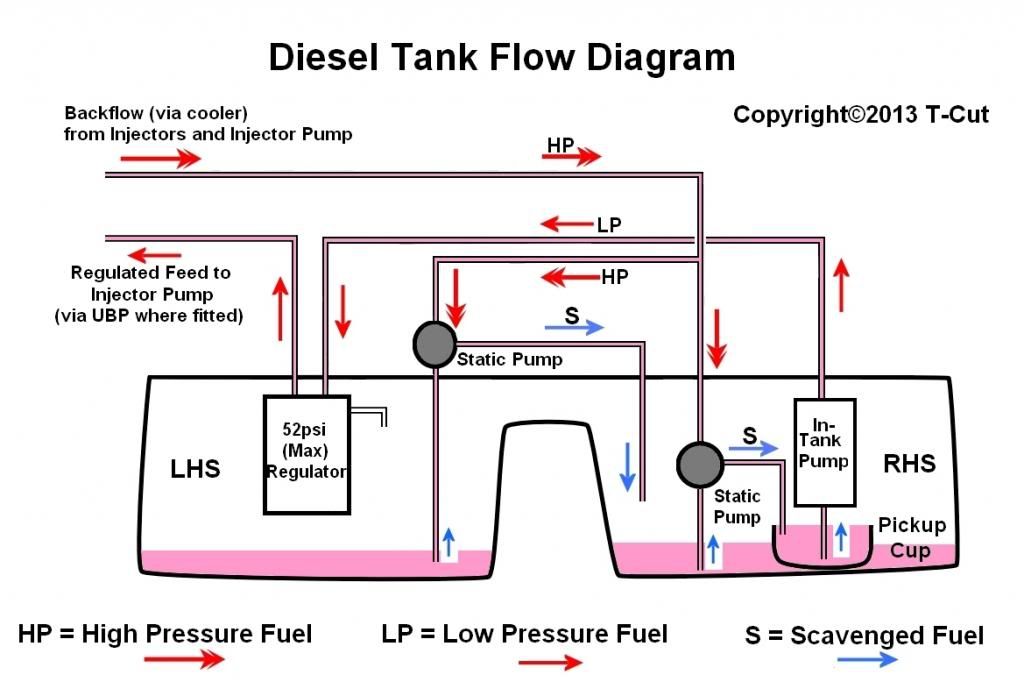

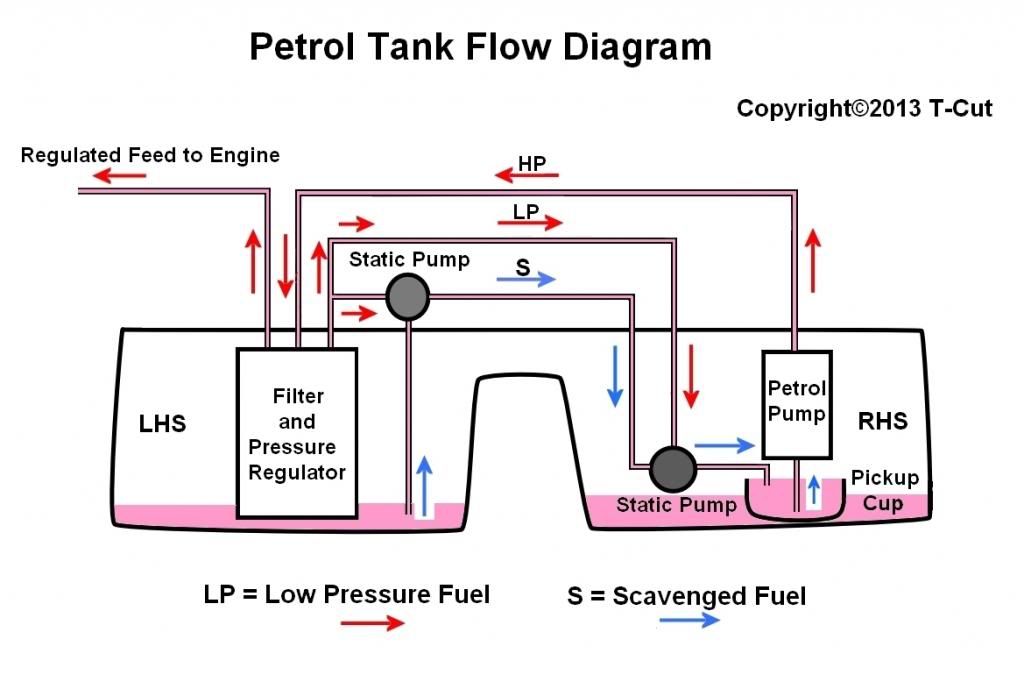

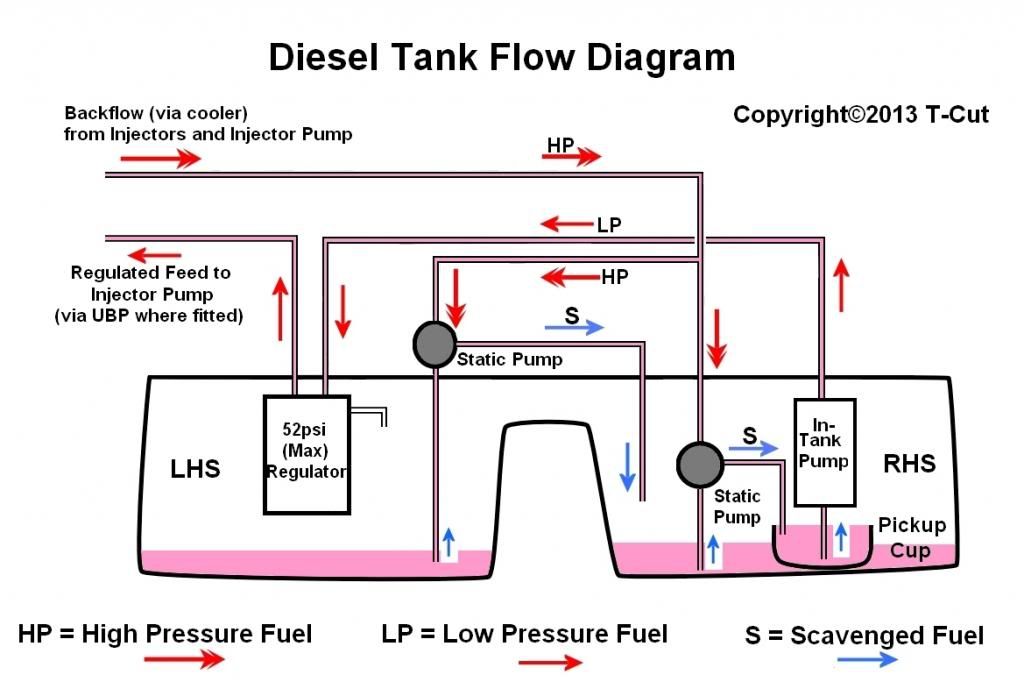

Fuel in the RH side must be available to the ITP and is maintained by two venturi (static) pumps. These transfer fuel from the LH side to RH side and are driven by the high pressure backflow from the injector pump. This schematic might explain it.

This diagram only shows the liquid flows and vapour handling is an added complication. It also omits the fuel cooler to keep it simple. Everything shown here is actually inside the tank.

If there's any interest, I can post the write up that goes with the drawing.

TC